Four methods to avoid rust of linear guide rail

Linear guide rails often encounter rust. Especially in the hot summer like now, the direct contact of the operator’s hands with the linear guide rail after sweating may also lead to the rust of the guide rail. How should we try to avoid rust on the surface of linear guide rail in daily use?

1. In order to prevent the guide rail from rusting, we need to keep the surface of the guide rail clean. The method of regular cleaning needs to be selected according to the nature of the surface of rust-proof objects and the conditions of use. After the surface is dried and cleaned, dry it with pure compressed air or dry it with a dryer at 120℃~170℃ or dry it with clean gauze before drawing antirust oil;

2. The pH value of human sweat is between 5 and 6, showing weak acidity, usually colorless or yellowish liquid, containing sodium, potassium, calcium and magnesium salts and a small amount of urea, lactic acid and citric acid. Once the sweaty hand comes into contact with the metal surface of the linear guide rail, it will form a sweat film on the metal surface, which will react electrochemically with the metal and cause certain corrosion to the metal. Therefore, hands should not touch the guide rail, and clean gloves, finger sleeves or other special tools should be worn when holding the guide rail;

3. The linear guide rail will rust, but the user is not familiar with the use of the linear guide rail. Generally speaking, the manufacturer will coat a layer of antirust oil on the linear guide rail before it leaves the factory to protect the linear guide rail from rusting. When many users put the linear guide rail in the warehouse, they will neglect to re-apply a layer of anti-rust oil regularly, and the protection ability of the linear guide rail will not exist after the anti-rust oil comes out of the factory. Therefore, it is necessary to lubricate and maintain the linear guide rail regularly.

4. It is wrong to store the guide rail with corrosive materials or put it on the ground for a long time. The linear guide rail needs to be stored in a normal temperature warehouse, and cannot be placed underground, which will accelerate the volatilization of antirust oil. If the linear guide rail is assembled inside the equipment and covered with aluminum alloy frame, it can be wiped regularly with antirust oil and lubricating oil to prevent the volatilization of lubricating oil.

5. If the linear guide rail must be exposed and in direct contact with the outside air, dust, etc., we need to increase the frequency of cleaning and maintenance, wipe off the grease and external dust impurities on the guide rail with a clean and dust-free special rag, and then apply lubricating oil or grease after cleaning. Regular maintenance can make the linear guide rail and mechanical equipment run stably for a long time.

Maintenance guide rails are critical.

Please pay attention to ARESWIN. We will bring you the latest industrial solutions and provide various guide selection. We have ten years of transmission experience, please contact us if there is a need.

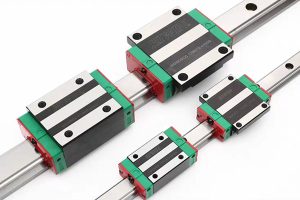

If your linear guide rail often rusts, try the above methods! If you need linear like HIWIN, PMI,TBI,THK or other types please contact Areswin Prescision Machinery Company, we will provide you a soulution for linear guide.

Our team can provide you with industrial solutions and product knowledge, please contact us without hesitation.Please check our website for more information: www.areswin.net