Ball screw noise is generally caused by the following factors.

1. After long-term use of the ball screw surface, the surface of the steel ball peels off, or the same problem exists in the cutting force surface of the screw shaft, which affects that the steel ball cannot pass through the track smoothly, resulting in vibration and noise before the nut and the shaft.

2. If the ball screw pair is used too loosely, the nut and screw of the ball screw pair will produce clearance, vibration and noise after a long time of use.

3. The balls in the original nut are all of the same size, tightly locked by the oil seal, and the noise is relatively low. When the steel balls are replaced because of wear and tear, in order to match good preloading and run smoothly, two kinds of steel balls with different diameters are usually used for installation. Once the load is added, it is difficult to run the nut.

Solution: Step 1. Loosen and unscrew the dust-proof sealing rings at both ends of the nut, inject lubricating oil with viscosity lower than ISO32 into the nut oil injection hole (the lower the viscosity, the better) to clean the nut, walk back and forth for several times within the effective stroke, then inject lubricating oil or grease with viscosity between ISO 32 and 68, and walk back and forth for several times. If the noise does not improve, perform the second step.

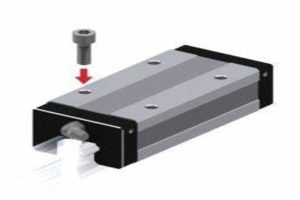

Step 2. Clean and observe whether the screw raceway is damaged, and the detachable nut is not damaged. First, use the hollow sleeve provided by the supplier (if there is no hollow sleeve with an outer diameter slightly smaller than the screw diameter and an inner diameter slightly larger than the outer diameter of the shaft end) to cover the shaft end, then slowly screw out the nut and check whether there is any damage at both ends of the nut ball circulating ring. If not, remove the balls (warning: it is not recommended to try if there is no experience), and comprehensively check whether there is any damage in the nut raceway.

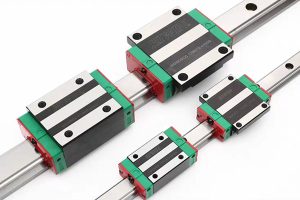

Step 3. Re-test and install the parallelism between the ball screw and the guide, as well as the installation of the end bearing of the screw and the concentricity of the bearing end installed at both ends. Straighten the screw with a straightening machine. If the noise continues, go to step 4.

Step 4. The cleaning of the removed bearing is divided into coarse cleaning and fine cleaning. In the container, respectively, the metal mesh bottom is placed first, so that the bearing does not directly contact the dirt in the container. During rough cleaning, if the bearing rotates with dirt, the rolling surface of the bearing will be damaged, so attention should be paid to it. In the crude cleaning oil, use a brush to remove grease and adhesive. After cleaning, turn to fine cleaning.